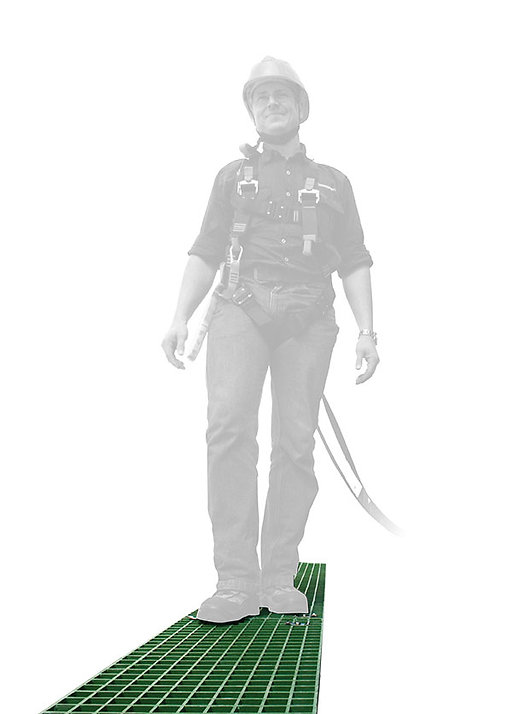

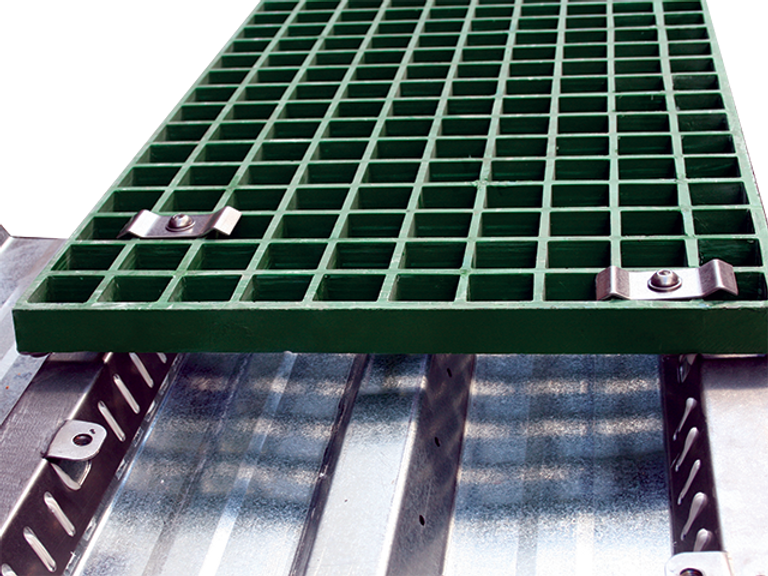

Heightsafety Line™ is a range of permanent engineered solutions for safe working-at-height access requirements when using Fall Arrest and or Rope Access Techniques. These uniquely patented designs incorporate durability and simplicity to ensure easy to use, and low maintenance height safety access solutions. With two decades of experience in the working at height industry we are able to provide cost-effective product support.

This will assist the end-users with the design, implementation, manufacturing, installation, maintenance and orientation training for their safe working at height anchoring system. Some end users occasionally have difficulties in identifying the requirements for a safe working at height solution. Our product support will minimise the risk by recommending the best-suited system for the maintenance access application.

Our broad distribution network and certified installers are able to provide a turnkey solution for all height safety access requirements.

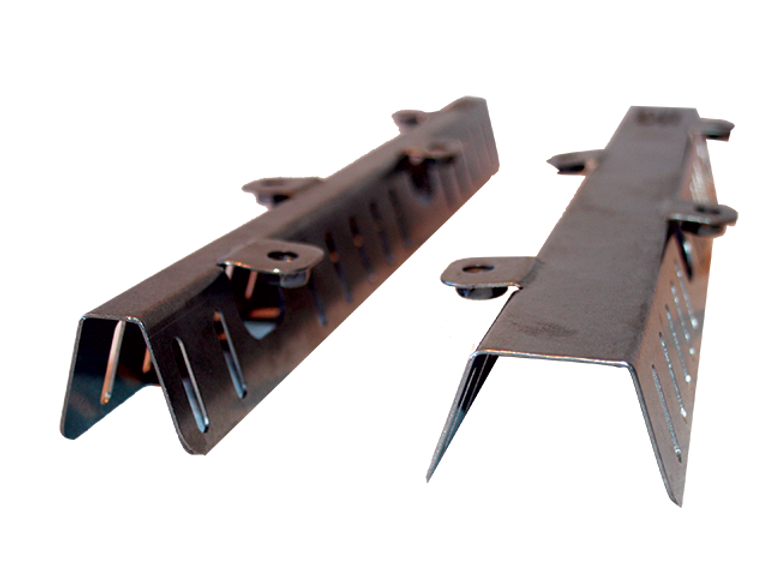

The quality of our product range is managed through a cerfied ISO 9001: 2015 Quality Management System that includes supported continual improvement plans and batch tests to guarantee a quality product every me.

The traceability of each component is guaranteed through its unique serial number that is clearly visible on the item itself. The serial number indicates the following: